Shapers Corner | Jonathan Matthews – Blusurf

Check out our Shapers Corner article with Jonathan Matthews from our May 2018 Issue!

What led you to start shaping wake surfboards and how was Blusurf born?

I began shaping because I wanted the ocean like board feel behind a boat and felt I could produce a better product than what was available in my local shops. I established Blusurf with focus on two things: custom shaped boards direct to consumer; constant exploration of performance materials in the ECO conscious market place. With many focused-on volume, I am committed to minimizing the environmental impact of board building without sacrifice in quality and performance.

How is your shaping influenced by your location?

With the majority of my time spent around boats, I am most influenced by the artificial endless wave and maximizing performance in a ten to fifteen-foot window.

Are there any new technologies you are integrating into your boards?

Constantly. I study the synergies across the Aeronautical, Auto and Surf industries to seek out composites and other fabrics to ensure I am offering an array of weight, strength and flex ratios.

What is unique about the boards you shape?

I shape each and every Blusurf board directly for the end user. I do not run stock models for a “one shape fits many”, rather, my philosophy is to truly offer a custom shaped and built board to maximize a riders time and enjoyment on the water.

Do you have a favorite model or board that you shaped? Why?

I do, team rider Trevor Miller’s signature model. This shape has a complex hull design based on relatively simplistic hydrodynamic concepts. I’ve really enjoyed shaping boards for Trevor over the years and this model is a fun blend of boats, power, finesse and rotational control. It started with Trevor looking at me sideways when he came into my shop to see what I was working on and instantly turned into high-fives the first time it hit the water.

What advice would you give to someone to find the perfect board?

Begin with being truthful about your riding abilities and goals, then find a shaper who will listen to you. It should be a fun and informative process, if it isn’t, move on.

What is your take on fin set-ups for wake surfing? Does it play a big role or just pop any old fins in and rip?

Fins can make or break your riding experience for sure. I tell folks all the time “try as many fins as possible” and encourage them to find different variations for the different boat wakes. I will set up a board ranging from twin to five fins based on their riding style and needs, in the end though fins are definitely not a one-size-fits-all element.

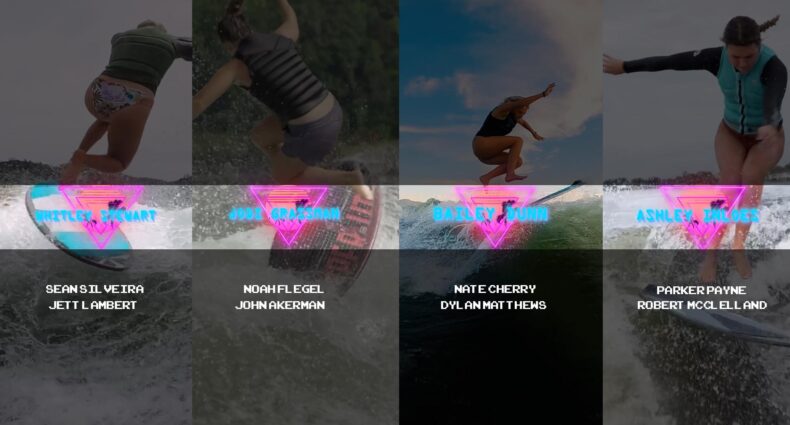

Blusurf tends to have a lot of athletes on the podium and a solid support group at the events. Was this something that happened organically or did you intend to build a solid team?

Thanks for noticing, I have been committed to building a top tier team of riders since the start – their performance on/off the water fuels the sport and constantly pushes my design and build approach which ultimately benefits Blusurf customers who are able to capitalize on the most modern materials, shapes, and boat wake knowledge.

What do you see as your biggest hurdle in shaping wakesurf boards? If you could wave a magic wand to change anything instantly what would it be?

I see my greatest hurdle on the building side with Epoxy resin cure times. If said wand existed, I’d wave it over the great minds creating the BIO Resins to have them figure out a mix which reached full cure in an hour!

For inquiries contact jonathan@blusurf.com | 425.236.9006